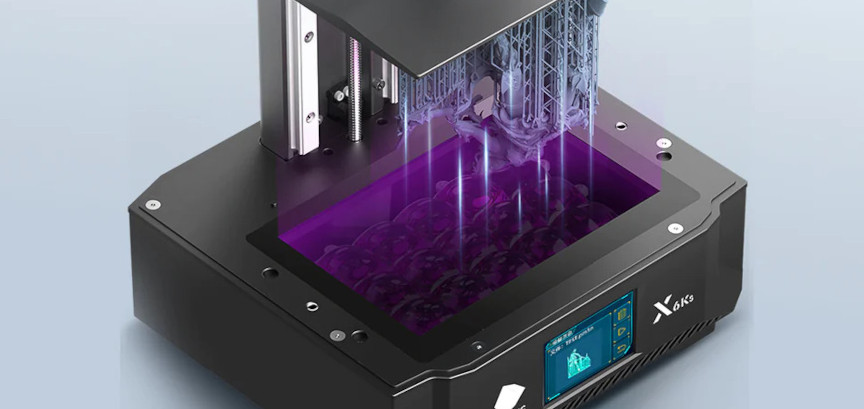

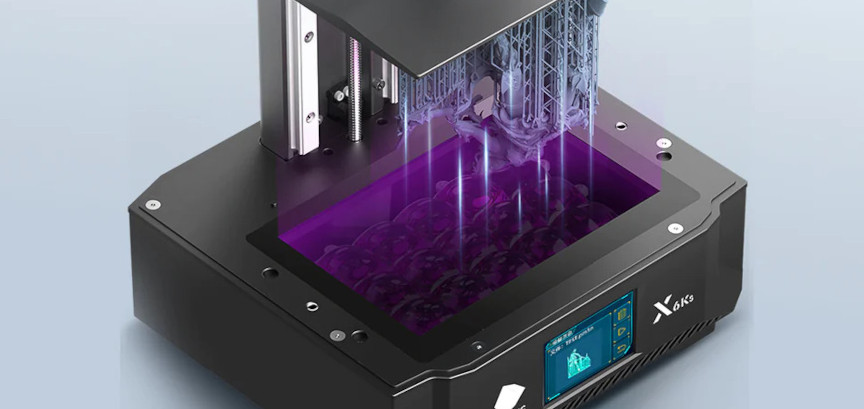

SLA printing, stereolithography or resine printing, is an added manufacturing technique that uses an ultraviolet light source to polymerize a photosensitive resin that layer by layer forms the final model. This technique allows creating pieces of complex shapes with high precision and detail. It has multiple uses, some of which are shown below:

Miniature Modeling

Using high-resolution resins allows you to print highly detailed models quickly at an affordable price. These models can later be painted with an airbrush or brush like any other conventional scale model.

Metal casting

Castable resins make it possible to use 3D printing for jewelry, as they allow detailed models to be printed that can be used in the metalworking process in the same way as a wax model without having to change any phase of the process.

Injection Moulding

High temperature resistant resins allow plastic injection molds to be printed and used for small-scale production, or as prototypes of a final metal mold.

Engineering

Resins with properties similar to ABS plastic (Acrylonitrile butadiene styrene) allow creating weather-resistant and impact-resistant pieces, which can be used directly not as a prototype, but as a final part.

Prototyping

The different types of photosensitive resins available for SLA 3D printing can facilitate the product design process, quickly creating functional prototypes of a final product.

Architecture

3D printing can also speed up the architectural design process, allowing highly detailed scale models to be created quickly.